How Temperature Influences RO Membrane Efficiency

As soon as one applies RO membranes, their performance depends significantly upon temperature, which also dictates how long they last. The silent factor of water temperature affects flux performance and salt rejection rates while changing fouling characteristics to impact overall system output performance. For companies utilizing RO Membranes Suppliers in UAE together with a professional Water Treatment Company in UAE, establishing knowledge about temperature effects enables continuous RO system stability.

Understanding the Relationship Between Temperature and RO Membranes

The standard reference temperature for RO membrane operation remains set at 25°C for proper functioning. The membranes undergo direct changes when temperatures fluctuate in hot regions such as the UAE.

Higher temperatures increase water molecule movement, which may appear beneficial initially. However, these positive effects can create severe consequences when proper control measures are lacking.

Impact of High Temperature on RO Membrane Performance

Increased Water Permeate Flow

Water becomes less viscous as temperatures rise, allowing membranes to pass water more easily. The increased permeability leads to higher permeate flow rates. While this may seem advantageous, unregulated temperature spikes can damage membranes over the long term.

Reduced Salt Rejection Efficiency

Membrane microscopic pores undergo slight expansion when exposed to elevated temperatures. This expansion allows dissolved salts to pass into the permeate stream, reducing salt rejection efficiency. Over time, this deterioration negatively impacts water quality and system stability.

Accelerated Membrane Aging

Membrane materials experience faster chemical deterioration at high operating temperatures. Continuous operation beyond recommended limits shortens membrane lifespan, increases replacement frequency, and raises operating costs, an important concern for clients working with RO Membranes Suppliers in UAE.

Temperature-Induced Fouling and Scaling Risks

Faster Fouling Rates

Biological activity intensifies as water temperature increases. Warmer conditions accelerate bacterial and microorganism growth, significantly increasing the risk of biofouling on RO membranes.

Increased Scaling Potential

Temperature affects mineral solubility in water. Elevated temperatures promote calcium carbonate precipitation, increasing the risk of scaling especially in the UAE’s high-TDS water environment.

Operating Temperature Limits for RO Membranes

Most RO membranes have a maximum safe operating temperature of 35°C. Operating beyond this limit without corrective measures can result in:

- Permanent membrane damage

- Increased salt passage

- Loss of mechanical strength

A reliable Water Treatment Company in UAE always applies to Temperature Correction Factors (TCF) during system design and operation.

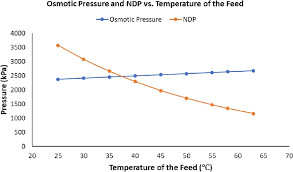

Temperature Correction Factor (TCF) Explained

The Temperature Correction Factor adjusts expected membrane performance based on feed water temperature. As temperature increases, the TCF rises, affecting pressure requirements and flow calculations.

Failure to apply for TCF leads to inaccurate performance data and improper system operation.

Challenges of High Ambient Temperatures in the UAE

Feed Water Temperature Fluctuations

Due to climatic conditions and prolonged storage, feed water temperature in the UAE often exceeds standard design values. Underground tanks, pipelines, and open reservoirs absorb environmental heat, increasing the temperature before water enters the RO system.

Thermal Stress on System Components

High temperatures affect not only membranes but also pumps, seals, and pressure vessels. System-wide temperature control is therefore essential.

Best Practices to Control Temperature Effects

Feed Water Cooling Solutions

Shading water storage tanks and installing heat exchangers before RO processing help stabilize feed water temperature and protect membranes.

Optimized Operating Pressure

Adjusting operating pressure based on temperature variations helps maintain consistent membrane performance while minimizing system stress.

Enhanced Pretreatment

Advanced pretreatment reduces temperature-induced fouling and scaling risks. Experienced Water Treatment Company in UAE providers implement effective filtration, anticipant dosing, and biological control as standard practices.

Role of RO Membranes Suppliers in UAE

Professional RO Membranes Suppliers in UAE provide temperature-tolerant membranes and expert operational guidance. Their local climate expertise ensures appropriate membrane selection for UAE conditions.

Used RO Membrane Performance and Temperature Sensitivity

Temperature Considerations for Used RO Membranes

Previously used membranes were more sensitive to temperature variations. When sourced from certified Used RO Membrane Suppliers, these membranes can still perform reliably under controlled temperature conditions.

Best Applications for Used RO Membranes

Used RO membranes are most suitable for low-temperature applications such as tertiary treatment, landscaping, and non-potable water reuse systems.

Monitoring Temperature for Long-Term Efficiency

Continuous temperature monitoring allows operators to:

- Adjust pressure and recovery rates

- Preventing premature membrane failure

- Maintain consistent water quality

Modern RO systems increasingly use smart sensors for real-time temperature and performance monitoring.

Future Developments in Temperature-Resistant RO Membranes

Advancements in membrane materials, polymer chemistry, and fouling-resistant coatings are improving membrane resilience in high-temperature environments. Leading RO Membranes Suppliers in UAE actively promote these innovations to support efficient operation in hot climates.

Conclusion

Temperature plays a decisive role in RO membrane efficiency, water quality, and membrane lifespan. Although higher temperatures may temporarily increase permeate flow, they also introduce serious risks such as reduced salt rejection, accelerated membrane aging, fouling, and scaling.

Successful RO system performance in the UAE requires effective temperature control supported by experienced RO Membranes Suppliers in UAE, trusted Used RO Membrane Suppliers, and a professional Water Treatment Company in UAE.

FAQs

1. What is the ideal operating temperature for RO membranes?

The standard reference temperature is 25°C, while most membranes can safely operate up to 35°C with proper correction factors.

2. Does higher temperature always improve RO system performance?

No. While higher temperatures increase permeate flow, they also reduce salt rejection and accelerate membrane degradation.

3. How does temperature affect RO membrane lifespan?

Operating at elevated temperatures shortens membrane life due to faster chemical and mechanical deterioration.

4. Can used RO membranes handle high temperatures?

Used membranes are more temperature-sensitive and should only be operated under controlled conditions, especially when sourced from Used RO Membrane Suppliers.

5. Why is temperature management more critical in the UAE?

High ambient temperatures and high-TDS water sources in the UAE increase fouling, scaling, and membrane stress, making temperature control essential.