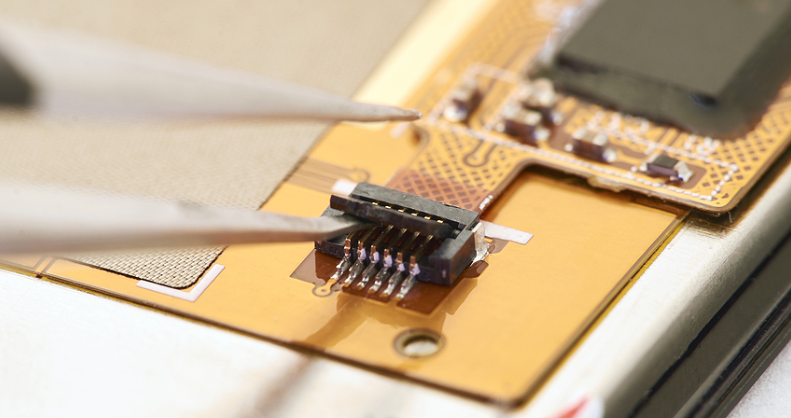

Top 4 Flexible PCB Assembly Manufacturers in China

The electronics manufacturing industry continues to evolve rapidly, with flexible PCB assembly becoming increasingly critical for modern electronic devices. From smartphones and wearables to medical devices and automotive electronics, flexible PCBs offer unique advantages including reduced weight, improved reliability, and enhanced design flexibility. China has emerged as a global leader in flexible PCB manufacturing, hosting numerous manufacturers that combine advanced technology with competitive pricing. This comprehensive guide explores the top 4 flexible PCB assembly manufacturers in China, helping you make an informed decision for your next project.

Top 1: PCBSync – Advanced PCB Assembly Excellence

PCBSync stands at the forefront of China’s flexible PCB assembly industry, distinguished by its commitment to high-end manufacturing capabilities and technical expertise. The company has built a strong reputation for handling complex PCB assembly projects that demand precision and reliability.

Key Features of PCBSync

High-End PCB Assembly Capabilities: PCBSync excels in advanced assembly techniques including BGA (Ball Grid Array), QFN (Quad Flat No-leads), and FPGA assembly. Their expertise extends to specialized components such as Xilinx FPGA assembly and Altera BGA assembly, making them the go-to choice for projects requiring sophisticated component integration. This capability is particularly valuable for clients developing high-performance computing systems, telecommunications equipment, and industrial automation solutions.

Multilayer PCB Manufacturing Expertise: One of PCBSync’s standout advantages lies in their proficiency with 8 to 24 layer PCB manufacturing. This capability enables the production of complex circuit boards that support high-density interconnections while maintaining signal integrity. Their advanced manufacturing processes ensure consistent quality across all layers, meeting the stringent requirements of aerospace, medical, and advanced computing applications.

HDI PCB Manufacturing: PCBSync offers comprehensive HDI (High-Density Interconnect) PCB manufacturing services, including blind vias and buried via PCB production. These advanced techniques allow for increased circuit density, reduced board size, and improved electrical performance – critical factors in modern miniaturized electronic devices.

Rigid-Flex PCB Solutions: Understanding the diverse needs of modern electronics, PCBSync provides rigid-flex PCB manufacturing services. This technology combines the benefits of rigid and flexible circuits in a single board, offering enhanced reliability and design flexibility for applications where space constraints and mechanical stress are concerns.

Turnkey PCB Assembly: PCBSync offers complete turnkey PCB assembly services with 100% original components sourcing. This commitment to authentic components eliminates the risks associated with counterfeit parts, ensuring product reliability and longevity. Their established relationships with authorized distributors guarantee component authenticity and traceability.

Quick Turn Prototyping: For clients operating on tight schedules, PCBSync provides quick turn prototyping services, enabling rapid iteration and faster time-to-market for new products.

Disadvantages

Despite its many strengths, PCBSync has some limitations to consider. The company does not provide 24-hour delivery services, which might be challenging for extremely urgent projects. Additionally, while their pricing is competitive for the quality offered, they are not the cheapest option in the market. PCBSync also does not focus on single-layer PCB manufacturing, concentrating instead on more complex, multi-layer solutions.

Top 2: RayPCB – Comprehensive Manufacturing Solutions

RayPCB has established itself as a comprehensive electronics manufacturing services provider, offering end-to-end solutions for flexible PCB assembly needs. Their full turnkey service encompasses PCB manufacturing, SMT assembly, and components sourcing, positioning them as a true one-stop solution for clients seeking streamlined project management.

Key Features of RayPCB

Rogers PCB Manufacturing Leadership: RayPCB has earned recognition as one of the best Rogers PCB manufacturers in China. Rogers materials are high-frequency laminates used in demanding applications such as RF/microwave circuits, automotive radar systems, and high-speed digital circuits. Their expertise in working with these specialized materials sets them apart in the industry.

Trusted Electronic Manufacturing Services: With a proven track record, RayPCB has built trust with clients worldwide through consistent quality and reliable service. Their Flexible PCB Assembly services demonstrate their comprehensive understanding of flexible circuit requirements and manufacturing challenges.

Advanced Flexible PCB Capabilities: RayPCB offers flexible PCB manufacturing for circuits up to 8 layers, accommodating a wide range of applications from simple flex circuits to complex multilayer flexible boards. Their expertise in flexible PCB design and manufacturing ensures optimal performance in applications requiring repeated flexing or complex 3D configurations.

Extensive PCB Manufacturing Range: The company provides PCB manufacturing services for boards ranging from 6 to 32 layers, combining high quality with reasonable pricing. This broad capability range allows them to serve diverse market segments, from consumer electronics to industrial equipment.

High-End Prototype Assembly: RayPCB specializes in high-end prototype PCB assembly, supporting clients through the critical development phase where quality and reliability are paramount. Their prototyping services enable thorough testing and validation before committing to full production runs.

Disadvantages

RayPCB’s focus on high-end, high-quality solutions means their pricing is positioned at the premium end of the market. While the quality justifies the cost for many applications, budget-conscious projects might find their rates challenging. Additionally, they do not offer 24-hour quick turn services, which could be limiting for extremely time-sensitive projects.

Top 3: Flexpcb.org – Specialized Flexible Circuit Solutions

Flexpcb.org has carved out a niche in the flexible PCB assembly market through their specialized focus on flexible circuit technologies. Their expertise centers on applications where flexibility, durability, and space optimization are critical design requirements.

Key Strengths

The company offers excellent capabilities in single and double-sided flexible PCBs, multilayer flexible circuits, and rigid-flex combinations. Their manufacturing processes are optimized for flex-specific challenges such as coverlay application, stiffener attachment, and dynamic flex applications. Flexpcb.org maintains competitive pricing for flexible PCB projects, making them attractive for mid-volume production runs.

Their engineering support team provides valuable design-for-manufacturing feedback, helping clients optimize their flexible PCB designs for manufacturability and cost-effectiveness. The company’s shorter lead times for flexible PCB projects make them suitable for projects with moderate urgency requirements.

Top 4: Hillmancurtis – Balanced Approach to PCB Assembly

Hillmancurtis rounds out the top four with their balanced approach to flexible PCB assembly, offering a mix of capabilities that serve a broad customer base. Their strength lies in providing reliable, consistent quality across various PCB types and complexities.

Notable Capabilities

The company provides comprehensive PCB assembly services including both flexible and rigid-flex options. Their assembly capabilities span from simple to moderately complex designs, with particular strength in consumer electronics applications. Hillmancurtis offers competitive pricing for standard flexible PCB assemblies, making them accessible for companies with budget constraints.

Their customer service and communication are consistently rated highly, providing smooth project management and responsive support throughout the manufacturing process. The company maintains good quality control standards with reasonable turnaround times for standard projects.

Conclusion

Selecting the right flexible PCB assembly manufacturer in China depends on your specific project requirements, budget, and timeline. PCBSync leads the pack with their high-end assembly capabilities and multilayer expertise, ideal for complex, demanding applications. RayPCB offers comprehensive turnkey services with particular strength in Rogers materials and high-quality manufacturing. Flexpcb.org provides specialized flexible circuit solutions with good value, while Hillmancurtis offers a balanced approach suitable for a wide range of applications.

When choosing a manufacturer, consider factors beyond price alone: technical capabilities, quality standards, component sourcing practices, and customer support all play crucial roles in project success. By carefully evaluating your needs against each manufacturer’s strengths, you can select the partner best suited to bring your flexible PCB project to life.