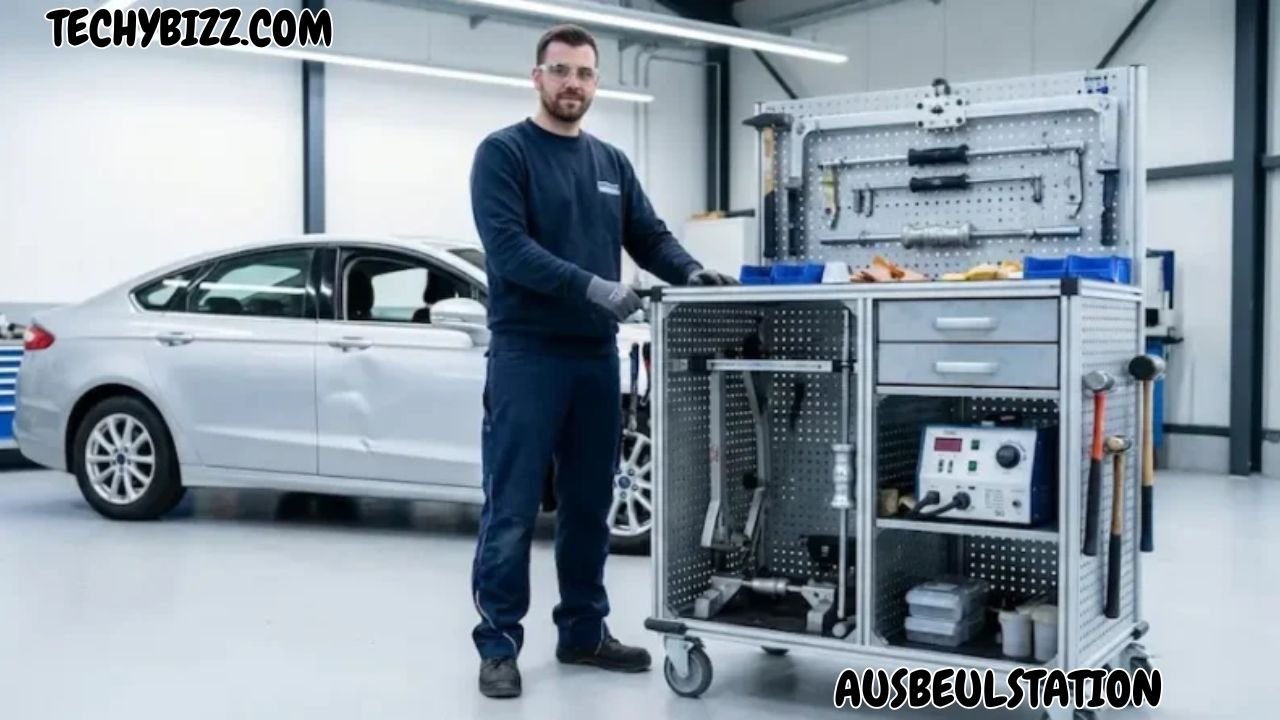

Ausbeulstation: A Complete Informational Guide to Modern Dent Repair

An ausbeulstation is an essential piece of equipment in modern vehicle body repair, providing a controlled and efficient way to correct dents, surface deformations, and structural irregularities on automotive panels. As vehicle designs evolve and materials become more complex, the role of the ausbeulstation becomes even more vital in restoring a car’s original shape while maintaining the integrity of its exterior finish. Its use reduces unnecessary filler work and helps maintain factory paint, making it a preferred solution for professional repair shops.

In today’s repair environment, an ausbeulstation allows technicians to work with precision and confidence. It centralizes tools and techniques into a single workstation, enabling consistent results even when working on challenging panel shapes or deep dents. By using specialized pulling, welding, and leveling methods, the ausbeulstation offers a more refined and streamlined approach to damage repair.

For workshops focused on efficiency, customer satisfaction, and long-term durability of repairs, adopting an ausbeulstation is a strategic investment. It improves workflow, reduces repair times, and ensures high-quality workmanship. As industry expectations continue to rise, the ausbeulstation remains a cornerstone of professional body repair operations.

Understanding the Purpose of an Ausbeulstation

The ausbeulstation serves as a dedicated hub for dent correction, allowing technicians to restore panels without relying heavily on sanding or filler material. Its purpose extends beyond surface-level improvements, offering a structural approach to returning metal to its original contour. By incorporating controlled pulling forces, heat application, and precise adjustments, the ausbeulstation acts as a highly reliable system for high-quality restoration.

Working with an ausbeulstation ensures that the repaired panel regains its factory shape with minimal distortion. This level of accuracy is crucial in maintaining vehicle aerodynamics, panel alignment, and long-term durability. Compared to traditional methods, the ausbeulstation minimizes unnecessary paint work and avoids weakening the metal through excessive grinding.

As more vehicles feature lightweight materials, the ausbeulstation becomes increasingly important. It supports delicate repairs that require a fine balance of force and finesse, especially on modern steel and aluminum surfaces. Its adaptability to different panel types makes it a universal solution in the automotive repair industry.

How an Ausbeulstation Works in Professional Repair

The ausbeulstation operates through a coordinated process designed to maximize precision while minimizing damage to the surrounding vehicle surface. It begins with assessing the deformation and determining the best approach based on the material and depth of the dent. Technicians rely on the ausbeulstation’s tools to attach pulling points, whether through welding studs or using adhesive pulling tabs.

Once attachment points are secured, controlled force is applied to gradually lift the dented area. The ausbeulstation allows incremental adjustments, ensuring the metal returns smoothly and evenly to its correct shape. During this stage, technicians combine pulling with gentle tapping or heat to relieve tension and refine the contour.

The final steps involve removing attachment points, smoothing any remaining irregularities, and inspecting the panel for accuracy. By following this methodical workflow, the ausbeulstation consistently delivers high-end results that align with industry standards for professional body repair.

Key Advantages of Using an Ausbeulstation

One of the biggest advantages of the ausbeulstation is its ability to repair damage without compromising the original paint surface. This reduces the need for repainting, which in turn lowers costs and preserves vehicle value. It also allows technicians to focus on restoring the original integrity rather than masking damage through cosmetic fixes.

Another major benefit is consistency. Because the ausbeulstation centralizes the tools and process, technicians can achieve predictable high-quality results regardless of dent size or location. This helps build customer trust and ensures long-term performance of repaired panels.

Additionally, the ausbeulstation supports faster repair times. Its organized structure and powerful tools reduce manual labor, speeding up the dent correction process significantly. For busy workshops, this efficiency translates into increased productivity and greater workflow stability.

Using an Ausbeulstation on Different Materials

Modern vehicles feature a variety of materials, including steel, aluminum, and composite mixtures. The ausbeulstation is designed to handle each of these materials effectively by providing adjustable controls and adaptable techniques. When working with steel, the system allows strong welding connections and robust pulling force, making it ideal for deeper or structural dents.

Aluminum panels require more careful handling, as they conduct heat differently and have a higher tendency to stretch. The ausbeulstation compensates with tailored settings that prevent overheating and ensure clean pulling action. This level of control is crucial in preserving the integrity of lightweight aluminum structures.

For composite or non-metal panels, technicians often rely on adhesive pulling methods rather than welding. The ausbeulstation offers the flexibility needed to work safely on these surfaces while still achieving optimal results. This adaptability ensures that the ausbeulstation remains useful across a wide range of modern vehicle designs.

Choosing the Right Ausbeulstation for a Workshop

Selecting the right ausbeulstation depends on the specific needs of a repair workshop. Factors such as the types of vehicles serviced, frequency of repairs, and available workspace all influence the decision. Higher-end models offer advanced controls, multiple pulling options, and greater durability, making them ideal for busy professional shops.

Smaller workshops may prefer a compact uitstation that still delivers strong performance but requires less space. Mobile versions allow technicians to move between service bays, enhancing flexibility in multi-vehicle environments. Regardless of size, the chosen ausbeulstation should be reliable, easy to operate, and equipped with essential features for both steel and aluminum work.

Investing in the right ausbeulstation ensures that technicians can meet customer expectations and handle a wide spectrum of repair challenges. By providing consistent power, precision, and versatility, it becomes a long-term asset for any workshop looking to elevate its repair capabilities.

Maintaining an Ausbeulstation for Long-Term Performance

Routine maintenance is essential for keeping an ausbeulstation functioning at peak performance. Regular inspection of cables, connectors, and welding tips ensures safe and efficient operation. Cleaning components after each use prevents buildup that can interfere with electrical contact or pulling accuracy.

Technicians should also monitor cooling systems and ventilation openings to prevent overheating during extended repair sessions. Proper storage of small tools and consumables keeps the workstation organized and ready for immediate use. By implementing a consistent maintenance schedule, workshops extend the lifespan of their investment and reduce unexpected downtime.

In addition to physical upkeep, technicians benefit from ongoing training to stay current with evolving vehicle materials and repair techniques. Understanding how to maximize the capabilities of an ausbeulstation ensures that it continues to deliver high-level performance over many years.

Conclusion

An ausbeulstation is a cornerstone of modern vehicle body repair, offering unmatched precision and efficiency in restoring damaged panels. Its ability to combine controlled pulling, accurate force application, and compatibility with multiple panel materials makes it indispensable for professional workshops. Through its structured workflow, technicians can deliver high-quality, repeatable results that preserve vehicle aesthetics and structural integrity.

As automotive design continues to advance, the ausbeulstation will remain vital in meeting the demands of new materials and body shapes. Workshops that integrate this technology gain a significant advantage in repair speed, quality, and customer satisfaction. With proper use and maintenance, an ausbeulstation becomes a long-lasting and essential tool for any serious repair environment.

By understanding its purpose, functionality, and benefits, technicians and shop owners can make informed decisions that enhance the efficiency and professionalism of their repair operations.